- We work with global industries!

Tubes/Pipes that comply with ASTM A270, ASME-BPE, 3A, and BS-4825 standards are commonly used in the pharmaceutical, biotechnology, and food industries for sanitary applications. These standards ensure that the tubes/pipes meet specific requirements for cleanliness, surface finish, and material composition, making them suitable for hygienic processes and preventing contamination.

1. ASTM A270: This standard specifies the requirements for seamless and welded austenitic stainless steel sanitary tubing intended for use in applications requiring a high level of hygiene and cleanliness. The tubes are commonly used in food, dairy, and beverage industries, as well as in pharmaceutical and biotechnology applications.

2. ASME-BPE: The ASME-BPE (BioProcessing Equipment) standard is specifically designed for the pharmaceutical and biotechnology industries. It provides guidelines for the design, materials, construction, and testing of equipment used in bioprocessing applications, including sanitary tubes/pipes. The standard ensures that the tubes meet the stringent requirements for cleanability and sterilizability.

3. 3A: The 3-A Sanitary Standards are widely recognized in the dairy and food processing industries. They establish criteria for the design and fabrication of equipment used in the production and processing of food products. 3-A standards for tubes/pipes focus on hygiene and cleanability, making them ideal for use in food and dairy applications.

4. BS-4825: This British Standard specifies the requirements for stainless steel tubes and fittings for the food and chemical industries. The standard covers both welded and seamless tubes, ensuring they meet the necessary hygiene and cleanliness criteria for these industries.

In summary, tubes/pipes complying with these standards are of high quality, designed for sanitary applications, and ensure the safety and purity of products in industries where cleanliness and hygiene are critical factors. They are suitable for use in various industries, such as pharmaceuticals, biotechnology, food processing, and dairy.

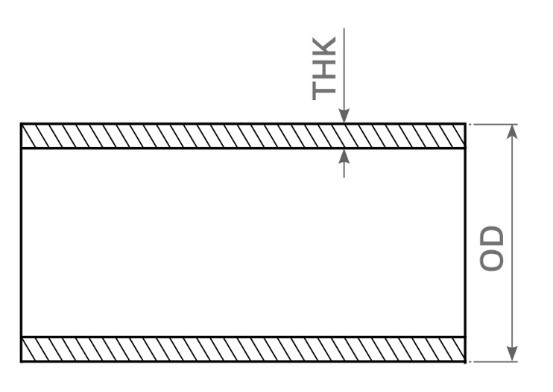

|

SIZE (in) |

OD (mm) |

THK (mm) |

|

1/2 |

12.70 |

1.65 |

|

3/4 |

19.05 |

1.65 |

|

1 |

25.40 |

1.65 |

|

1 1/2 |

38.10 |

1.65 |

|

2 |

50.80 |

1.65 |

|

2 1/2 |

63.50 |

1.65 |

|

3 |

76.20 |

1.65 |

|

4 |

101.60 |

1.65 |

|

SIZE (in) |

OD (mm) |

THK (mm) |

|

1/2 |

12.70 |

1.65 |

|

3/4 |

19.05 |

1.65 |

|

1 |

25.40 |

1.65 |

|

1 1/2 |

38.10 |

1.65 |

|

2 |

50.80 |

1.65 |

|

2 1/2 |

63.50 |

1.65 |

|

3 |

76.20 |

1.65 |

|

4 |

101.60 |

2.11 |

|

SIZE (in) |

OD (mm) |

THK (mm) |

|

1/2 |

12.70 |

1.20 |

|

3/4 |

19.05 |

1.20 |

|

1 |

25.40 |

1.60 |

|

1 1/2 |

38.10 |

1.60 |

|

2 |

50.80 |

1.60 |

|

2 1/2 |

63.50 |

1.60 |

|

3 |

76.20 |

1.60 |

|

4 |

101.60 |

2.0 |